MACHINERY

MACHINERY

MACHINERY

MACHINERY FOR BOTTLES & CONTAINERS

MACHINERY FOR BOTTLES & CONTAINERS

POLYCARBONATE(PC) BOTTLES MFG. MACHINE

POLYCARBONATE(PC) BOTTLES MFG. MACHINE

POLYCARBONATE(PC) BOTTLES MFG. MACHINE

THE DESIGN & MECHANISM OF 5 GAL. PC BOTTLES MACHINE.

PLAMA PMBMS-SERIES ABM MACHINES ARE DESIGNED THE WELL-PROVEN BASIC CONCEPT OF THE HITHERTO KNOWN BLOW MOULDING MACHINE AND THE LATEST TECHNICAL STATE OF THE ARTS. SINCE THE INCEPTION OF THE BLOW MOULDING MACHINERY ENGINEERS HAVE BEEN IDENTIFIED WITH MANY OF THE LATEST TECHNICAL ADVANCES OF THE INDUSTRY. RECENTLY PLAMA PMBMS-SERIES ABM MACHINE ARE POSITIVELY RECOMMENDED FROM ALL OF THE USER FOR THEIR HIGH PRODUCTIVITY AND LONG TERM RELIABILITY. PLAMA PMBMS- SERIES ABM MACHINE SYSTEMS ARE EMPLOYED IN A LARGE NUMBER OF PRODUCTS APPLICATIONS AND MARKETS, AND PRODUCE A WIDE RANGE OF PRODUCTS FROM THE SIMPLEST TO THE MOST COMPLEX FROM 10LTR JERRY CAN TO 30LTR, FROM 40 LTR TO 180 LTR DRUMS, FROM 220LTR TO 500LTR DRUM, ALL KINDS OF PLASTIC TOYS, CAR PARTS, INDUSTRIAL PARTS, FURNITURE PARTS, 220 LTR DRUMS. PLAMA PMBMS- SERIES ABM MACHINE SYSTEMS SUPPLY MELTING CAPACITY FROM 150KG TO 400KG PER HOUR, AND INJECTION CAPACITY OF ACCUMULATOR HEAD FROM 1KG TO 60KG. SURELY MORE BIGGER INJECTION CAPACITY OF ACCUMULATOR HEAD ARE AVAILABLE. THE EXCELLENT ENGINEERING OF THE PLAMA PMBMS-SERIES ABM MACHINES ARE EMPHASIZED BY THE IMPRESSIVELY LOW NOISE LEVEL FOR THE SIZE OF PLANT, AT WHICH THESE BLOW MOULDING MACHINES OPERATE IN PRODUCTION. ACCORDING TO THE CONTAINER SIZE, THE WEIGHT OF THE CONTAINERS AND THE SHAPE OF THE CONTAINERS, THE FOLLOWING MACHINE MODELS ARE AVAILABLE

- PLAMA PMBMS-A100D; FROM 15LTR TO 20LTR PE JERRY CANS

- PLAMA PMBMS-A110D; FROM 15LTR TO 30LTR PE JERRY CANS

- PLAMA PMBMS- A95S ; FROM 3 GAL. TO 6 GAL. PC CONTAINERS

- PLAMA PMBMS-A100S; FROM 40LTR TO 60LTR DRUMS

- PLAMA PMBMS-A110S; FROM 60LTR TO 160LTR DRUMS

- PLAMA PMBMS-A120S; FROM 180LTR TO 220LTR DRUMS

- PLAMA PMBMS-A150S; UP TO 500LTR CONTAINER AND LARGE VOLUME PACKAGING

"A" IS MEAN; ACCUMULATOR PARISON DIE HEAD SYSTEM

"D" IS MEAN; DOUBLE STATION MOULD PLATEN

"S" IS MEAN; SINGLE STATION MOULD PLATEN

"P" IS MEAN; PARISON WALL THICKNESS CONTROL

"T" IS MEAN; FULLY AUTOMATIC TRIMMING DEVICE

MOULD SPECIFICATION OF 5 GALLON VOLUME

1. BOTTLE SHAPEROUND TYPE WITH HANDLE

2. RAW MATERIALPOLYCARBONATE

3. MATERIAL WEIGHTAPPROX.--- CAVITY;750-780 grs

SCRAP;225 grs

4. PRODUCTION FIGURES APPROX. 80-90 CONTAINERS PER HOUR.

5. EXTRUSION HEAD 1(ONE) HEAD

6. MOULD CAVITY 1 CAVITY x 1 MOULD. 1 UNIT

MOULD MATERIAL FOR 5 gal. VOLUME

- MOULD MATERIAL FOR MAIN CAVITYAL-ALLOY 7075 (DURALUMIN)

- INSERT MATERIAL FOR NECK PARTSKD 11

- INSERT MATERIAL FOR FLASH POCKET OF BOTTOMNAK 80

- GUIDE PINSKD 11

- BACK PLATE OF THE MOLDSKD 11

- EXPECTED LIFE OF THIS MOULD5 YEARS OVER

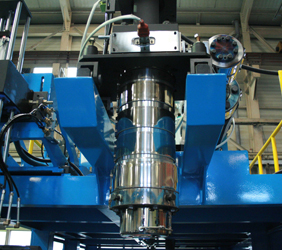

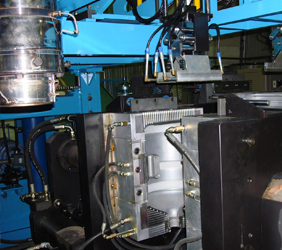

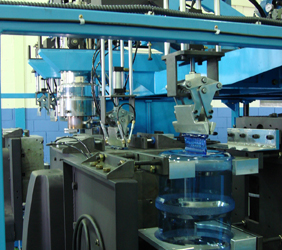

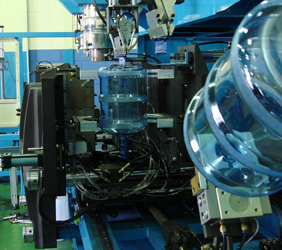

7. MAIN PARTS OF 5 gal PC BOTTLES MFG. MACHINE

5 gal pc mc1

5 gal pc mc2

5 gal pc mc3

5 gal pc mc4

5 gal pc mc5

5 gal pc mc6

5 gal pc mc7

8. VIDEO CLIP FOR 5 gal PC BOTTLES MFG. LINE

-

5 GAL PC MC

9. 5 gal BOTTLES

5 gal pc bottles1

5 gal pc bottles2

10ltr pc bottles1

10ltr pc bottles2

5 gal pc bottles3